Risks and cons of increasing performance

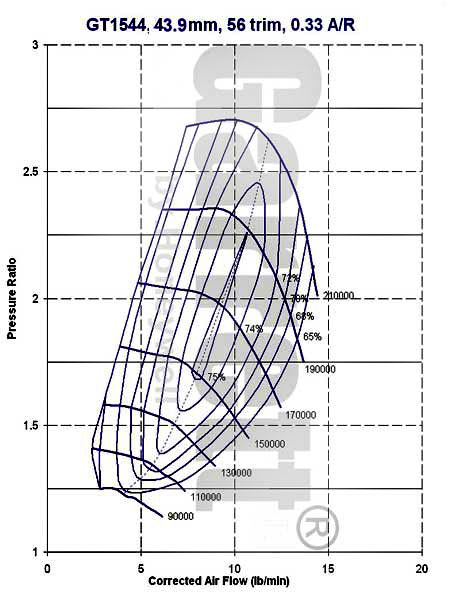

The most common reason is to keep the maximum load limits. The manufacturer should not use any part to use 100% load. He has to maintain any tolerance. The greater tolerance remains the longer part will last. Generally most at risk resides Article turbocharger. For example, at 1.9 JTDm turbine there is a surge-line, which limits power around 175 hp. Power 150 hp is therefore very close to the red line. Late fuel injected (typically after the intervention of the length injection map) turbine is heating up, and if the desired pressure is too high, there could come damage to the rotor due to temperature and pressure. Therefore, by the modification there is necessary to keep the air supply, which was calculated by the turbo manufacturer for the given model. You can find it in the compressor map (picture).

Exceeding these limits leads to its gradual destruction. Another very common reason for destroying the turbo to death, or partially functional regulation. By the turbo with variable control regulation, the carbon is storied due to engine operation, the blades can jam. Depending on what position the blades jam, either low pressure turbo makes and a car does not move enaugh (just need to clean), or a high, car falls into a safe mode for dangerously high pressure. Sometimes with the original software car run as usual and after the increase will fall into Safe Mode. This is due to the higher gas pressure in dysfunctional regulation or poorly modified software, when there is the requirement of a pressure higher than the breakpoint.

Another risk there is a bad condition of turbo-pressure hoses. Hoses from the turbo to the intercooler and from intercooler to intake manifold are often etched by oil released from the turbine. If such hose is inflated by the high pressure, it is increasing the likelihood of rupture. Another problem there is flywheel and clutch. Flywheels in JTD at all are sc. dual mass.

They are assembled by two concentric cylinders, which can be rotated slightly to each other. Springs in this flywheels mitigate impacts from engine and the vibration transmitted to the clutch and transmission are minimized. With an increase in performance there may occur flywheel vibrations. It is most obvious in the range of 1700-2300 rev / min, but can also occur above. The software is always necessary to debug for the car one, to avoid such a vibration. First, they are both uncomfortable and they damage the flywheel. When are the flywheel stops ripped, the car will remain out of service! Clutch also has its limits. The modified software causes, that the more powerful engine is able to overcome the cohesion of the clutch and slipping appears. Than, for example, if the clutch slipps for a 5 seconds at fifth gear, it will get worn more than by the 50 common starts at 1. gear. Therefore, the software must always adjust the clutch. Maximum torque of diesel engine could be found around 1700-2300 rev / min, there is the greatest risk of slipping clutch and flywheel vibration here. Approximate maximum torque values for the DMFs are 320N.m for JTD 77 kW, 360-380Nm for the other 1.9, 380-400N.m to 2.4 JTDM will also 500N.m. Similar limits are for vehicles with clutch Alfa Romeo. Fiat used unfortunately labile clutch, which keeps the smaller moment (50N.m less)

Transmissions, differentials and axles are not fundamental problem in concern Fiat, perhaps except for axle shafts in 2.4 JTD 20V 129kW, which is consistent with the 1.9 16v and tripoits are touchy to load. CR pump and injectors suffer, when working with high pressure. They are working at full pressure above the 3500rpm. The pressure is regulated by DRV - needle valve in the pump. The increase of pressure from 1600 bar to 1700 bar is not as dangerous as a long ride at high rpms. But the increasing of pressure at low speeds shorters a life. (power-rail Novitec powerbox). So good software and the clever driver = insignificant shortening of engine life. The engine does not suffer for good modification. In keeping with the AFR (air to fuel ratio) there is no significant increase in temperature. Simply, if engine does not smoke, it's good. Why then is the vehicle life decreased for improved performance? Most drivers who want to improve performance, ride in aggressive style. Greater stress of undercarriage parts, clutch, turbo, hoses, etc. An adequate effort loses its life . So how to do that to be stronger, but not to shorten my life? I got to meet the following requirements: First required Turbo pressure in the software calculated in accordance with the recommendation of turbo manufacturer. Second AFR calculated to no smoking vehicle. 3rd The increase in torque extended, that the clutch is not slipping and no flywheel vibration even at full throttle appear. 4th To ride with a sense to use the full power at shorter sections. Do not drive with full load with cold engine and let the engine run for ½ minutes at idle before switching off. Remember that a well-written software does not change the parameters for partial load (0-80%) and in itself can not damage the engine. With good software, damage can arise only as a result of insensitive and aggressive driving.